SmartGen | Panning Sand Requires You

Application of HMC9000S+AIN16-C+AIN16-PT+HRM3300

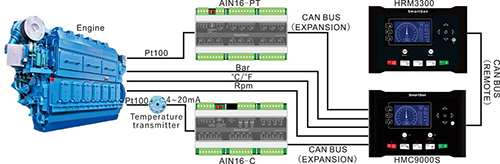

About 30 nautical miles away from a costal port in the beautiful Zhanjiang city, Guangdong Province, there was a huge ship of nearly 10,000 tons sand pumping ship. The two 12-cyclinder water pump engines are controlled by HMC9000S, and the 12 cylinder temperatures of the engines are detected by the expanded analog input module AIN16-PT. The temperature of 8 shafts is detected by the expanded analog input module AIN16-C, and the shaft temperature signal is converted from PT100 to 4~20mA current type signal through the temperature transmitter to the AIN16-C. The AIN16-C then transmits it to the diesel engine controller HMC9000S through CANBUS (EXPANSION) communication, and finally displays the real-time temperature and protection of the shaft. HMC9000S transmits the engine information to the remote control module HRM3300 in cab through CANBUS (REMOTE) communication, and can also control engine start/stop remotely through HRM3300.

Project Control System Introduction

HMC9000S engine controller: can be widely used in marine emergency units, main propulsion units, DG units or water pump units. Its remote monitoring module interface enables remote monitoring, which can remotely control engine start, stop, etc.

HMC9000S

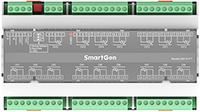

AIN16-PT Analog Input Module---16-way PT100 Sensor Input Module

AIN16-C Analog Input Module---16-way 4~20 mA Sensor Input Module

HRM3300 remote control module suits for the remote monitoring of HMC9000S engine controller

Typical Application of Marine Controller Communication

Site Pictures

Sand Pumping Ship

HRM3300 in Cab

Staff Operating HRM3300

Water Pump Engine

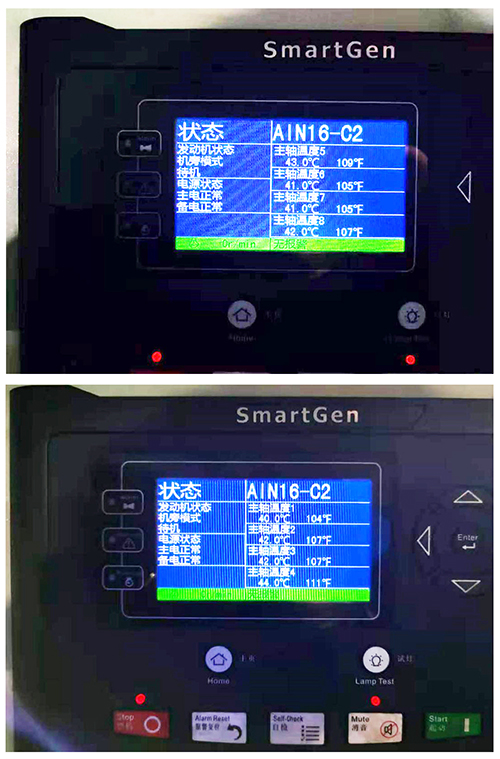

Water Pump Engine Cylinder Temperature

Water Pump Engine Main Shaft Temperature

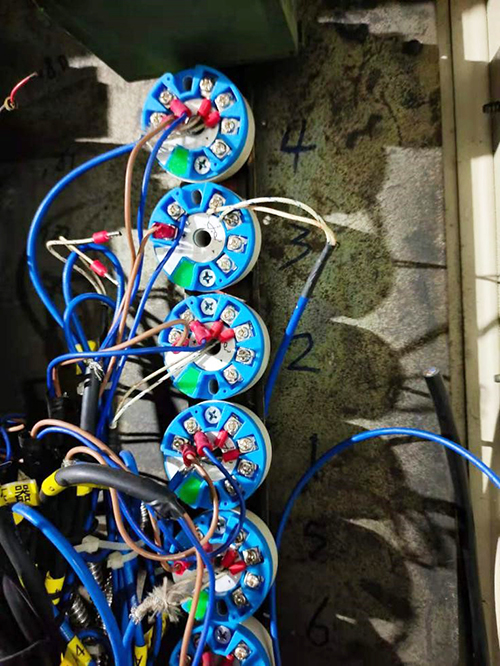

PT100 to 4~20mA Temperature Transmitter

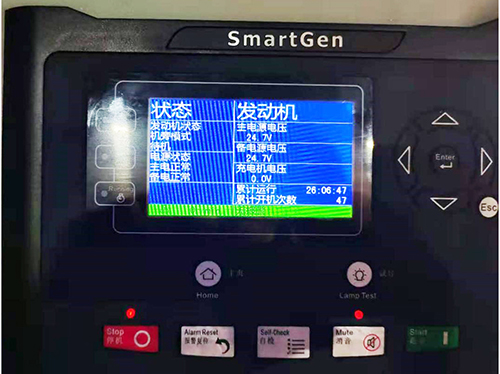

HMC9000S engine partial parameters

Common Fault Analysis:

1. HMC9000S and AIN16 communication failure:

Fault cause:

- CAN H and CAN L of CANBUS (EXPANSION) communication are reversed;

- CANBUS (EXPANSION) communication did not short circuit the CAN L and 120 Ω matching resistor on the controller;

- If the distance of CANBUS (EXPANSION) communication line is too long, SGCAN300 relay conversion module (MSC or RS485 communication to optical fiber) should be added.

2. Inaccurate display of temperature or pressure sensor:

Fault cause:

- Sensor curve setting is wrong;

- Sensor is broken.

3. HMC9000S and HRM3300 communication failure:

Fault cause:

- CAN H and CAN L of CANBUS (REMOTE) communication are reversed;

- CANBUS (REMOTE) communication did not short circuit the CAN L and 120 Ω matching resistor on the controller;

- If the distance of CANBUS (REMOTE) communication line is too long, SGCAN300 relay conversion module (MSC or RS485 communication to optical fiber) should be added.