SmartGen | The Lean Improvement Project Competition of SmartGen (Fifth Phase)

---Continuous improvement without limits

With the approaching of the New Year, we bid farewell to the special 2020 and welcome the hopeful 2021 with enthusiasm.

As the old year ends and the new year begins, the lean improvement of SmartGen is still on fire and vigorously blooms her vitality.

"The Lean Improvement Project Competition of SmartGen (Fifth Phase)" was held on the training room on the afternoon of Feb. 4th.

There are 8 projects in this competition. Compared to the previous four phases, the depth and breadth have been greatly improved. All five elements of management objectives QCDSM (Quality, Costing, Deadline, Safety, Morale) were involved.

Two winning projects are:

1. Shell seal improvement project of R&D Center: The material is changed from solid to liquid, and the production and assembly method is changed from manual to automatic, which improves the degree of automation, conforms to the characteristics of Industry 4.0 and applies the TRIZ theoretical knowledge. This project not only improves production efficiency, but also reduces costs while ensuring the quality.

2. Order placement timeliness improvement project of Production Center: By reorganizing and optimizing the physical flow and value flow, the timeliness of production order placement is greatly improved. This improvement will not only speed up the overall inventory turnover, but also ensure the delivery time of customers in a timely and fast manner.

The highlights and benefits of each improvement have injected vitality and power into the company’s continuous lean development.

General manager Cui Wenfeng and directors of each center participated as judges during the process and made wonderful and pertinent comments. After the presentation, Mr. Cui issued certificates of honor to the winners! Wow, there also came the red envelopes~~

Continuous lean is the only way to practice the company’s strategy. We have been firmly on the road to closely around the company’s values of “Innovation, Focus, Lean-Better” and continue to build the innovation and improvement culture of SmartGen!

SmartGen | 1562TEU "Maogang Shanghai" with SmartGen Controller

1562TEU Container Ship "Maogang Shanghai"

On January 13, 2021, the 1562TEU container ship "Maogang Shanghai", which was manufactured by Zhejiang Hexing Shipyard and classified into CCS, was successfully launched into the water. At present, it has been successfully towed to the anchorage for the next stage of equipment commissioning. The ship power station uses three 400kW diesel gensets as the main genset (the original engine is Yuchai YC6TD655L-C20 marine ECU diesel engine), the total capacity of the power station is 1200kW and 500kW shaft genset is used under navigation. SmartGen provides the ship with one-stop power station management solution from engine control to main switchboard control.

Schematic diagram of SmartGen marine engine intelligent control and power station power management solution

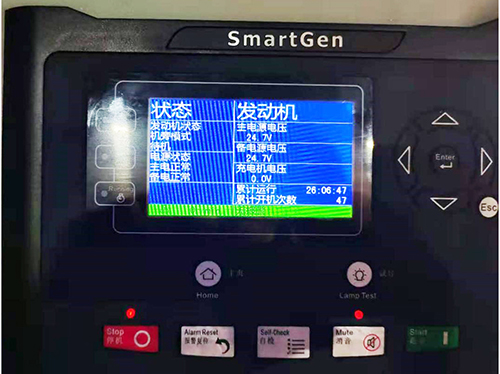

In order to promote the reliability and automation of this ship’s automatic power station management system, this ship’s main genset is equipped with MGCP100B-2 diesel engine control box developed by SmartGen for marine ECU to realize the automatic start/stop of main genset, engine safety protection and ECM parameter monitoring functions. Its main control unit applies HMC9000A engine controller. The control box is equipped with a built-in HEP300 electronic potentiometer, which can convert the passive digital speed signal from the switchboard into a 0~5V signal with higher precision to achieve higher precision load adjustment. The HRM3300-3 remote control box with the same operating interface as the local control box, is installed on the alarm detection platform.

Meanwhile, the main switchboard adopts the multi-master power management system built by SmartGen HMC6 power management controller to realize the on-demand automatic scheduling and real-time protection of 3 main gensets + 1 shaft genset + 1 emergency and mooring genset, which greatly improves the power supply reliability of the power station.

Since SmartGen mature products with full intellectual property rights and CCS certification are used from diesel engine control to power management module of the main switchboard, the whole system follows the same design style, with more friendly HMI, easier operation and more efficient crew training.

During the commissioning process of the power station, SmartGen’s on-site service personnel worked together with the project management personnel of Hexing shipyard, ship owner representatives, genset manufactures and main switchboard manufacturers, to ensure that the power station passed the acceptance of the CCS with high standard. This is another successful case of SmartGen marine control products in high-end marine application field in 2020.

Topology of SmartGen marine engine intelligent control and power station power management solution

Main switchboard of power management system built by SmartGen HMC6 power management controller

3 main gensets with SmartGen MGCP100B-2 diesel engine control box

SmartGen HRM3300-3 remote control box installed on the alarm detection platform

SmartGen | New HGM6100N(4G) Series Will Launch

Somebody imitates my front panel

Somebody imitates my back panel

Familiar figure, adding a new function, makes your controller more powerful and smarter

Cloud monitoring all-in-one HGM6100N(4G) series controller will be launched sooner

Easier for unit successfully connects with cloud server

Insert card---scan the code to register---unit in hand

Cost-effective

It is closer to our expectations for the controller

The classic reproduces the legend

Add cloud modem expansion board based on the HGM6100N series

The comparison of 4 models is as follows:

Product Highlights:

Cloud monitoring all-in-one design, supports SMS function.

Configure controller parameters via cloud server.

LCD display GPS position and cloud monitoring networking status.

For different countries and regions, different models of 4G expansion module are available.

Charging voltage, speed, water temperature, oil pressure display can select ECU or external analog sampling.

Compatible with various ECU engine communication (only available for CAN-4G model controllers).

www.smartgen.cn

SmartGen | Dual Power ATS Controller—HAT553V

Product highlights:

- Wide working temperature range (-40°C~+70°C), suitable for high altitude, alpine regions;

- Suitable for non-breaking, one-breaking and two-breaking switches;

- With RS422 isolated communication port, can choose RS422 or RS485 communication, applies ModBus-RTU communication protocol;

- 132x64 LCD with backlight, optional Chinese and English display;

- DC9-35V continuous power supply, with DC reverse connection protection function;

- Two-way DC power input (DC power redundancy design);

- With real-time clock, event log (50 pieces), scheduled start function;

- Suitable for 3-phase 4-wire, single phase 2-wire, 2-phase 3-wire;

- Personalized design and simple wiring;

- D-type USB port;

- IP65 protection level.

Controller Rear Panel

Typical Wiring Diagram

SGQ-N/T Application Diagram

Breaker (ACB) Application Diagram

Overall Dimensions and Cutout

SmartGen | Make Great Success with Small Controller

——Application of construction machinery product HEM4100

Rotary drilling rig, belonging to construction machinery, is a special construction machinery for bored pile drilling operation. It is widely used in municipal construction, highway and railroad bridges, high-rise buildings and other foundation construction. With different drill bits, it is suitable for drilling in various geologies such as clay, silt, sand, mucky soil, artificial backfill and stratum containing some pebbles and gravels, and can be adapted to the construction of weathered rock layers.

At present, the construction machinery engine is in the stage of updating the national Ⅱto nationalⅢemission standards. In this case, the nationalⅡengine is replaced by nationalⅢengine. SmartGen’s construction machinery product HEM4100 controller is used for transformation. The rotary drilling rig uses ECU engine as the power source. This case applies CAN J1939 of HEM4100 to communicate with engine ECU and achieves start and stop of HEM4100 through its start and stop button. The throttle (i.e. speed) is flexibly controlled by the throttle pedal device, and the engine speed, battery voltage, oil pressure and engine temperature are monitored in real time by HEM4100 to achieve normal operation of the rotary drilling rig.

Site Pictures

HEM4100 Wire Connection

HEM4100 Panel

Throttle Pedal

Rotary Drilling Rig Engine

Rotary Drilling Rig

HEM4100 Front Panel

HEM4100 main functions:

- Support relay, CAN BUS speed adjustment.

- USB, RS485 communication ports.

- 6-way analog suit for multi-type sensors.

- Event log, maintenance reminder.

- Applies to engine control systems like water pump, beacon, air compressor, construction machinery and so on.

SmartGen | Panning Sand Requires You

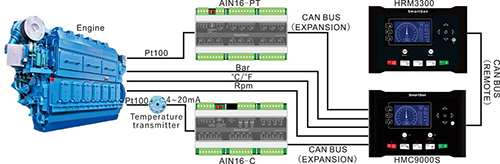

Application of HMC9000S+AIN16-C+AIN16-PT+HRM3300

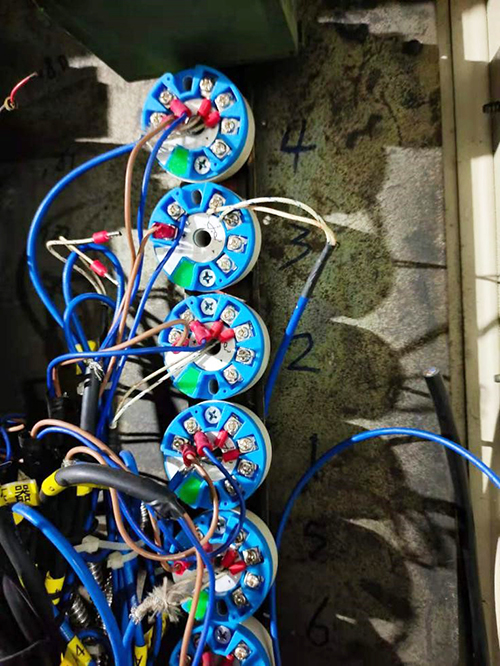

About 30 nautical miles away from a costal port in the beautiful Zhanjiang city, Guangdong Province, there was a huge ship of nearly 10,000 tons sand pumping ship. The two 12-cyclinder water pump engines are controlled by HMC9000S, and the 12 cylinder temperatures of the engines are detected by the expanded analog input module AIN16-PT. The temperature of 8 shafts is detected by the expanded analog input module AIN16-C, and the shaft temperature signal is converted from PT100 to 4~20mA current type signal through the temperature transmitter to the AIN16-C. The AIN16-C then transmits it to the diesel engine controller HMC9000S through CANBUS (EXPANSION) communication, and finally displays the real-time temperature and protection of the shaft. HMC9000S transmits the engine information to the remote control module HRM3300 in cab through CANBUS (REMOTE) communication, and can also control engine start/stop remotely through HRM3300.

Project Control System Introduction

HMC9000S engine controller: can be widely used in marine emergency units, main propulsion units, DG units or water pump units. Its remote monitoring module interface enables remote monitoring, which can remotely control engine start, stop, etc.

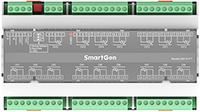

HMC9000S

AIN16-PT Analog Input Module---16-way PT100 Sensor Input Module

AIN16-C Analog Input Module---16-way 4~20 mA Sensor Input Module

HRM3300 remote control module suits for the remote monitoring of HMC9000S engine controller

Typical Application of Marine Controller Communication

Site Pictures

Sand Pumping Ship

HRM3300 in Cab

Staff Operating HRM3300

Water Pump Engine

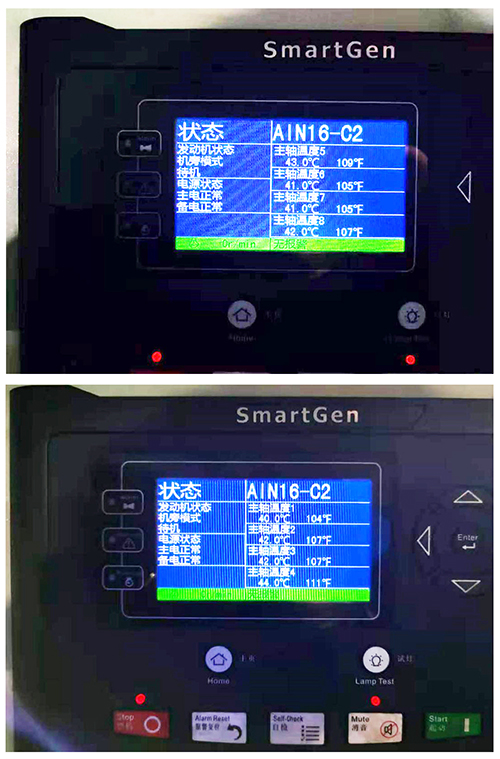

Water Pump Engine Cylinder Temperature

Water Pump Engine Main Shaft Temperature

PT100 to 4~20mA Temperature Transmitter

HMC9000S engine partial parameters

Common Fault Analysis:

1. HMC9000S and AIN16 communication failure:

Fault cause:

- CAN H and CAN L of CANBUS (EXPANSION) communication are reversed;

- CANBUS (EXPANSION) communication did not short circuit the CAN L and 120 Ω matching resistor on the controller;

- If the distance of CANBUS (EXPANSION) communication line is too long, SGCAN300 relay conversion module (MSC or RS485 communication to optical fiber) should be added.

2. Inaccurate display of temperature or pressure sensor:

Fault cause:

- Sensor curve setting is wrong;

- Sensor is broken.

3. HMC9000S and HRM3300 communication failure:

Fault cause:

- CAN H and CAN L of CANBUS (REMOTE) communication are reversed;

- CANBUS (REMOTE) communication did not short circuit the CAN L and 120 Ω matching resistor on the controller;

- If the distance of CANBUS (REMOTE) communication line is too long, SGCAN300 relay conversion module (MSC or RS485 communication to optical fiber) should be added.